Greater Cincinnati Water Works (GCWW) is a giant in the water treatment world, and it has to be. The Ohio River, recently deemed the second-most endangered river in the country, is constantly bombarded with pollutants from upstream factories and farming runoff, not to mention the occasional toxic disaster as seen recently in East Palestine. From tacking typhoid to developing new technologies with the Environmental Protection Agency, GCWW has always been ten steps ahead of many other metropolitan water plants. The history of GCWW can be felt in its significant scientific advancements and its stunning architecture, both of which draw visitors and niche enthusiasts from all over.

CityBeat had the chance to visit the historic GCWW campus in Cincinnati's California neighborhood. Scroll down to see photos from our tour with Jeff Swertfeger, superintendent of water quality at GCWW.

Photos by Aidan Mahoney

Photos: A Behind-the-Scenes Look at Greater Cincinnati Water Works' Testing and Treatment Facilities

By Madeline Fening on Fri, Apr 21, 2023 at 5:08 pm

Scroll down to view images

Page 1 of 2

Photo: Aidan Mahoney

The original pump station for GCWW was built in 1907. Its massive doors frame a set of rail tracks that allowed trains to pull into the cylindrical building to deliver the iron needed to build the pumps inside.

1 of 21

Photo: Aidan Mahoney

The pumping station brings water in from the Ohio River to the plant so GCWW can start the treatment process.

2 of 21

Photo: Aidan Mahoney

Some of the largest steam pumps ever built are housed in the pumping station at GCWW. While some of the pumps are no longer active, GCWW said they were kept in place for a different reason than pumping water. The colossal weight of the iron pumps keeps groundwater from pushing on the floor of the station and forcing it up out of the ground.

3 of 21

Photo: Aidan Mahoney

Old gauges that previously provided readings on water pressure and revolutions per minute are perfectly preserved at GCWW. Digital gauges do the work now, but enthusiasts of early American machinery still travel to GCWW to catch a glimpse of the brassy original equipment.

4 of 21

Photo: Aidan Mahoney

The inside of an old triple expansion steam engine at GCWW is another relic that draws visitors and fans of old steam engines.

5 of 21

Photo: Aidan Mahoney

Visitors and employees of GCWW can travel seven feet below the bottom of the Ohio River where temperatures hover at a cool 52 degrees year-round.

6 of 21

Photo: Aidan Mahoney

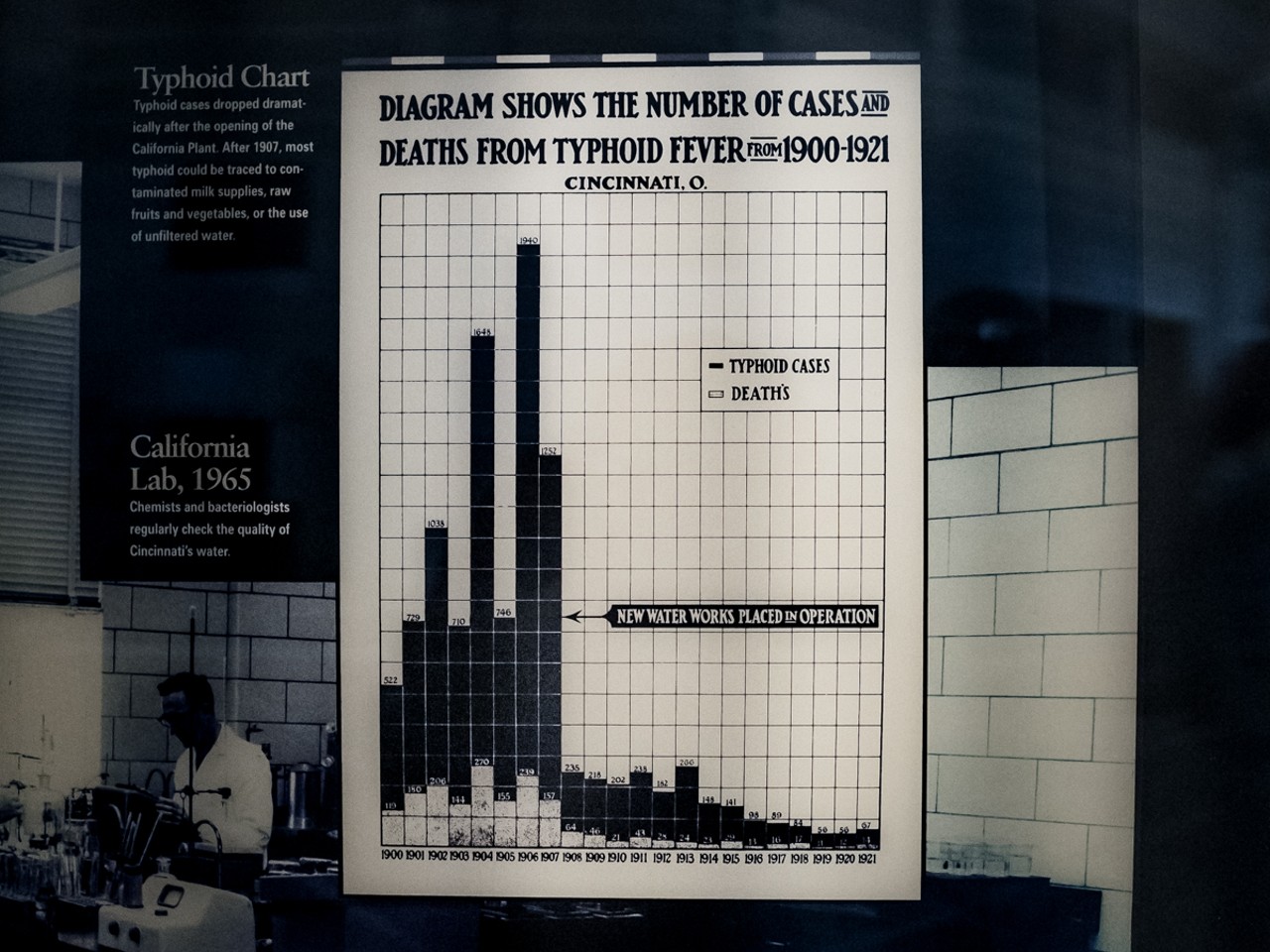

Jeff Swertfeger, superintendent of water quality at GCWW, told CityBeat that Cincinnati has been on the forefront of treating water-born illnesses since the outbreak of Typhoid in the early 20th century.

7 of 21

Photo: Aidan Mahoney

An expansive view of the room where sand tanks filter out particles in the water from the Ohio River. In person, the room's symmetry and color pallet has the feeling of a Wes Anderson movie, but the location was actually once submitted for consideration to Hollywood producers for a Batman movie.

8 of 21

Photo: Aidan Mahoney

Sand filters the water from the Ohio river after it's pumped into the system and treated with alkalizers. The grid system allows GCWW employees to walk through and monitor the water levels of each sand tank.

9 of 21

Photo: Aidan Mahoney

Water takes about two days to trickle all the way through 24-30 inches of sand on top of gravel and a drain. Particles within the water stick to the sand and remove impurities. Swertfeger told CityBeat the water looks perfectly clear after this process, which is the last step for many municipal water treatment departments across the country, but not at GCWW.

10 of 21

Photo: Aidan Mahoney

During the '70s, a spill of carbon tetrachloride in the Ohio River initiated the start of a project between the United States Environmental Protection Agency Water Research Center (EPA) and GCWW to develop a new filtration system for removing harmful chemicals from the water using activated carbon.

11 of 21

Photo: Aidan Mahoney

Pools of water that have already passed through the natural sand filters now through massive quantities of activated carbon. Swertfeger said this process is serving as a model for other municipalities across the country as the federal government looks to eliminate forever chemicals from the drinking water.

12 of 21

Photo: Aidan Mahoney

Swertfeger describes the tanks with 11 feet of activated carbon as "a giant Brita filter."

13 of 21

Photo: Aidan Mahoney

Because chemicals stick to the carbon during filtration, the carbon needs to eventually be cleaned for continued use. Large rooms with massive furnaces heat the activated carbon about every nine months. The process of "re-activating" the carbon so it's ready to filter more water requires 1,600 degrees of heat. The process requires steam to prevent the carbon from burning up, but Swertfeger said about 7% of the carbon is lost in the process. Air pollution control equipment then destroys the molecules so only carbon dioxide and water is emitted from the re-activation process.

14 of 21

Photo: Aidan Mahoney

As many learned during the height of the COVID pandemic, UV light is an effective disinfectant for viruses. Before the pandemic, in 2013, GCWW created an additional barrier for microbes by adding a UV light filtration step in its water treatment process. A large UV lightbulb sits inside pipes, disinfecting the water before safe levels of chlorine and fluoride are added.

15 of 21

Photo: Aidan Mahoney

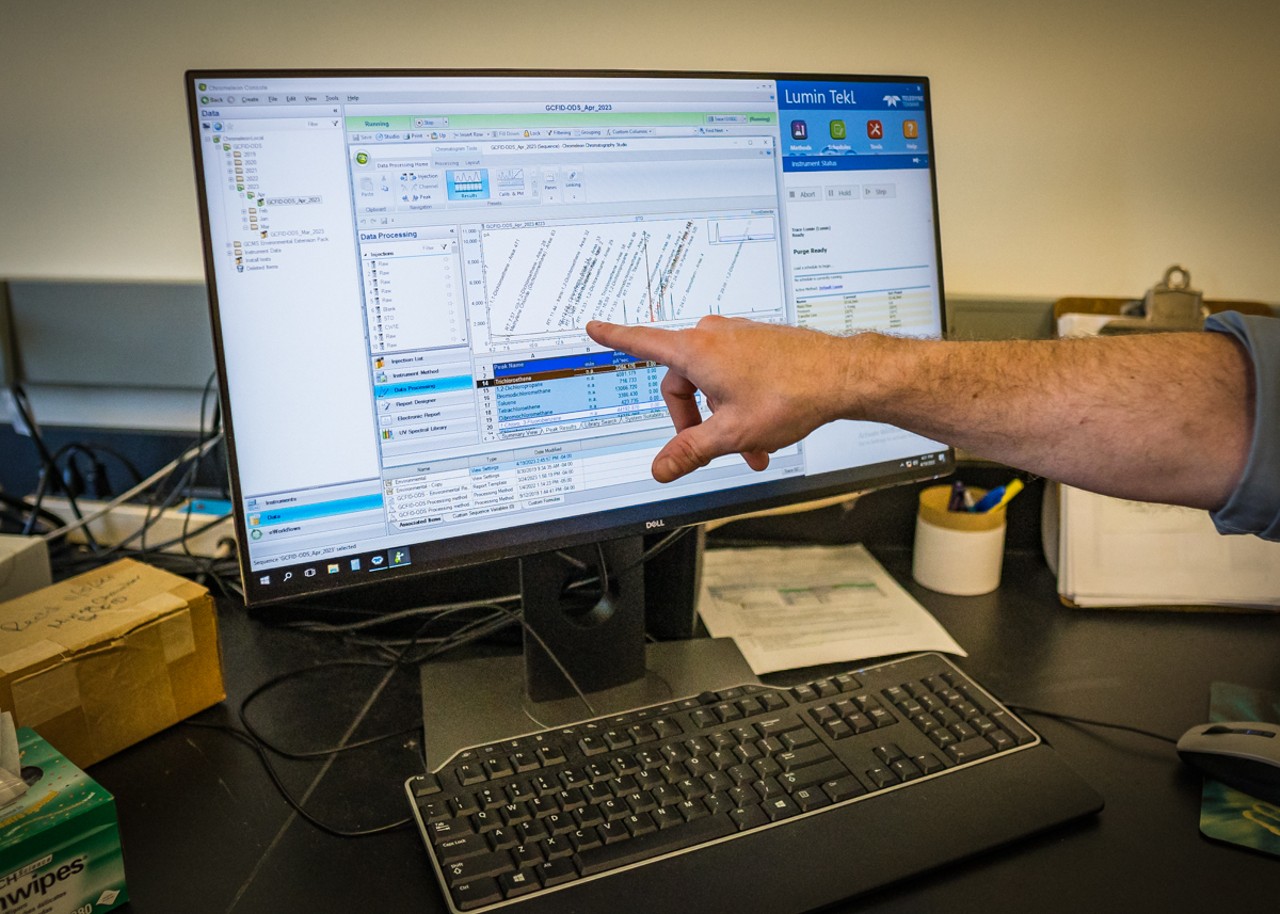

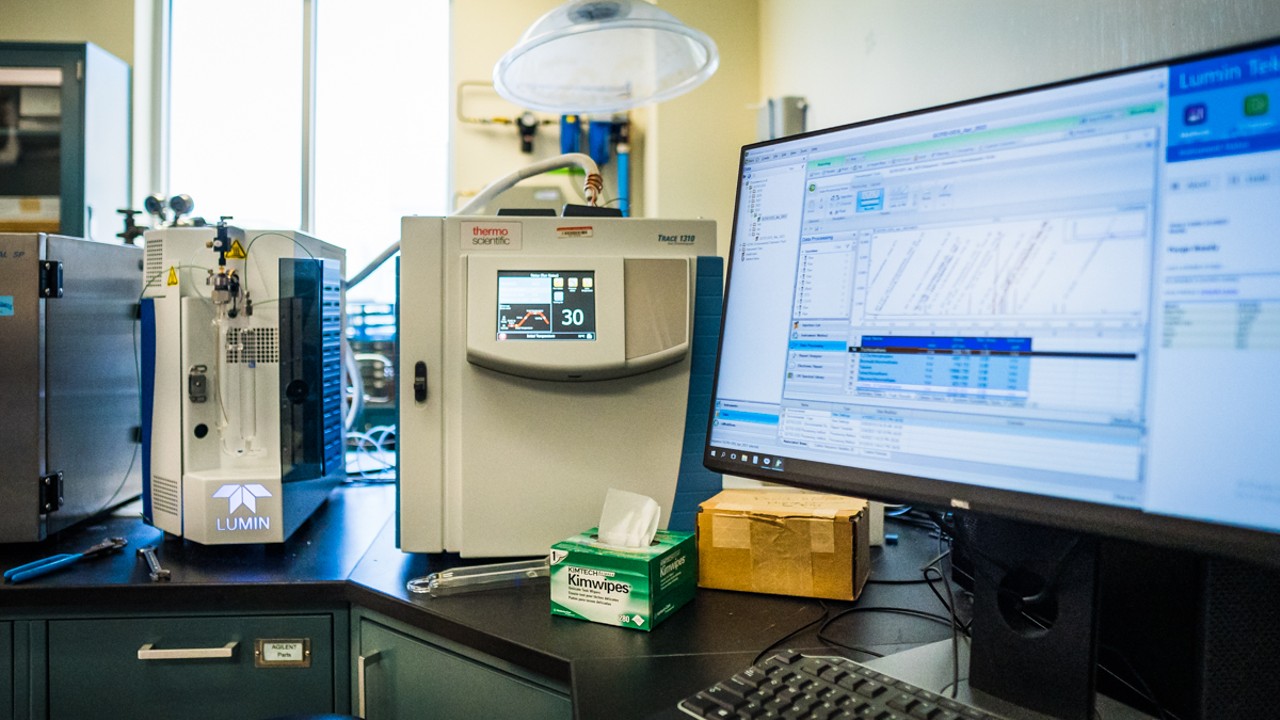

Lab employees at GCWW do hundreds of daily routine tests to measure chemicals in the water by parts-per-billion to determine water safety.

16 of 21

Photo: Aidan Mahoney

Water from each step of the filtration process is siloed into individual water lines so lab employees can perform tests.

17 of 21

Photo: Aidan Mahoney

Lab employees at GCWW do hundreds of daily routine tests to measure chemicals in the water by parts-per-billion to determine water safety.

18 of 21

Photo: Aidan Mahoney

Each year, hundreds of GCWW customers submit water samples from their homes or businesses to measure lead levels. If the water tests positive for lead, GCWW will work with the homeowner to find the source, which Swertfeger said is often the service line for houses built before 1920. GCWW also offers a lead "look-up map" where residents can enter their address and find out the material of their service line.

19 of 21

Photo: Aidan Mahoney

Lab employees at GCWW do hundreds of daily routine tests to measure chemicals in the water by parts-per-billion to determine water safety.

20 of 21

Page 1 of 2

- Local Cincinnati

- News & Opinion

- Arts & Culture

- Things to Do

- Food & Drink

- Music

- Cincinnati in Pictures

- About City Beat

- About Us

- Advertise

- Contact Us

- Work Here

- Big Lou Holdings, LLC

- Cincinnati CityBeat

- Detroit Metro Times

- Louisville LEO Weekly

- St. Louis Riverfront Times

- Sauce Magazine